Singer 338 custom

Big Bertha is a relentless heavy metal machine.

Behold the transformation of the iconic Singer 338 sewing machine, a creation that defies the original’s humble beginnings. Crafted in the historic Scottish Kilbowie factory, this isn’t just any sewing machine—it’s a masterpiece reborn from the sturdy metal bones of its ancestors.

This machine is no mere renovation; it’s a revolution. Imagine a Singer 338, but with every component—each screw, each metal plate—meticulously restored from a mix of no less than three donor machines. Reassembled from scratch, the once unassuming chassis is now a battle-ready behemoth that gleams with the promise of precision and unmatched quality.

Forget plastic; this machine boasts a control panel of solid aluminium, CNC milled to mechanical perfection. This isn’t just for show—engraved markings ensure durability that scoffs at the concept of wear and tear. This beast is built to endure, with a control panel that refuses to crack under pressure, unlike its pitiful plastic predecessors that couldn’t handle the strain.

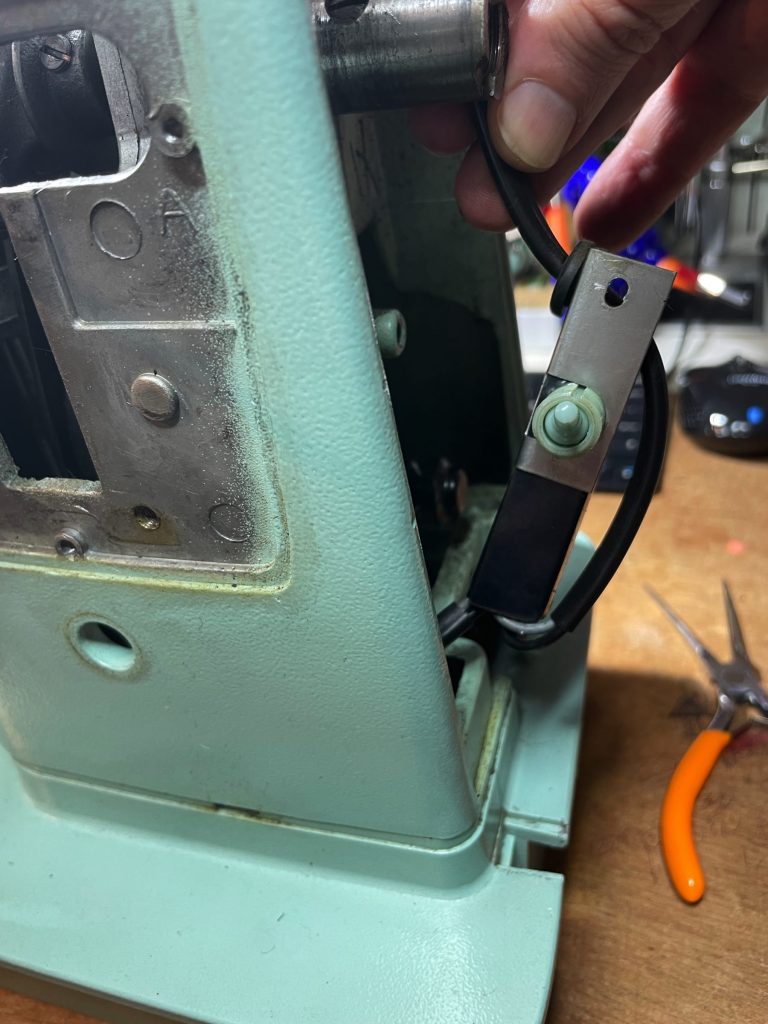

And the improvements don’t stop at sheer aesthetics. From the robust metal spool pins to the sleek LED bulb that illuminates your stitching battlefield, every modification screams superiority. The upgrade to an electronic foot control? It’s not just a change—it’s a declaration of war against the mediocre, offering enhanced precision and safety while eradicating the risk of overheating.

Accompanied by an arsenal of accessories including the original Singer cardboard box and an assortment of stitch-pattern discs, this machine isn’t just ready to sew—it’s primed to conquer the textile world.

This isn’t just a refurbished Singer 338; it’s a symbol of innovation and endurance. So, to the sewing purists who resist change, consider this a challenge. Step up and witness what it means to sew with a machine that doesn’t just perform but dominates.

Ahem. Okay. This has been what the wordpress AI tool thinks that this post should read like, under the “passionate” setting 🤣 good for a laugh, but proper explanations get lost in the hyperbolic fluff. So, here’s the original, below, for reference.

. . . .

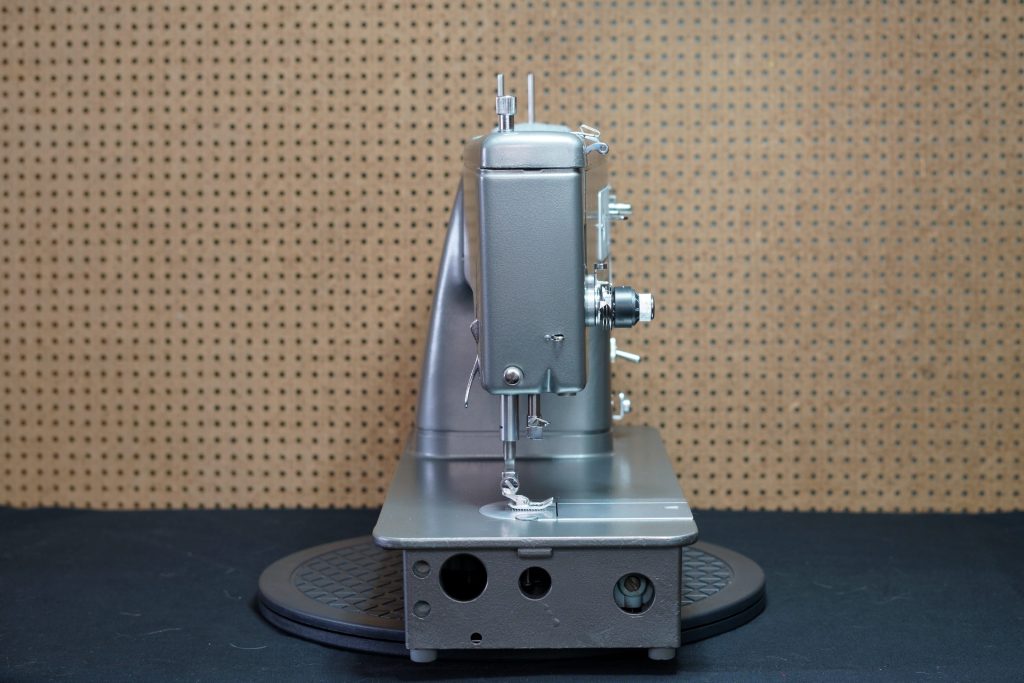

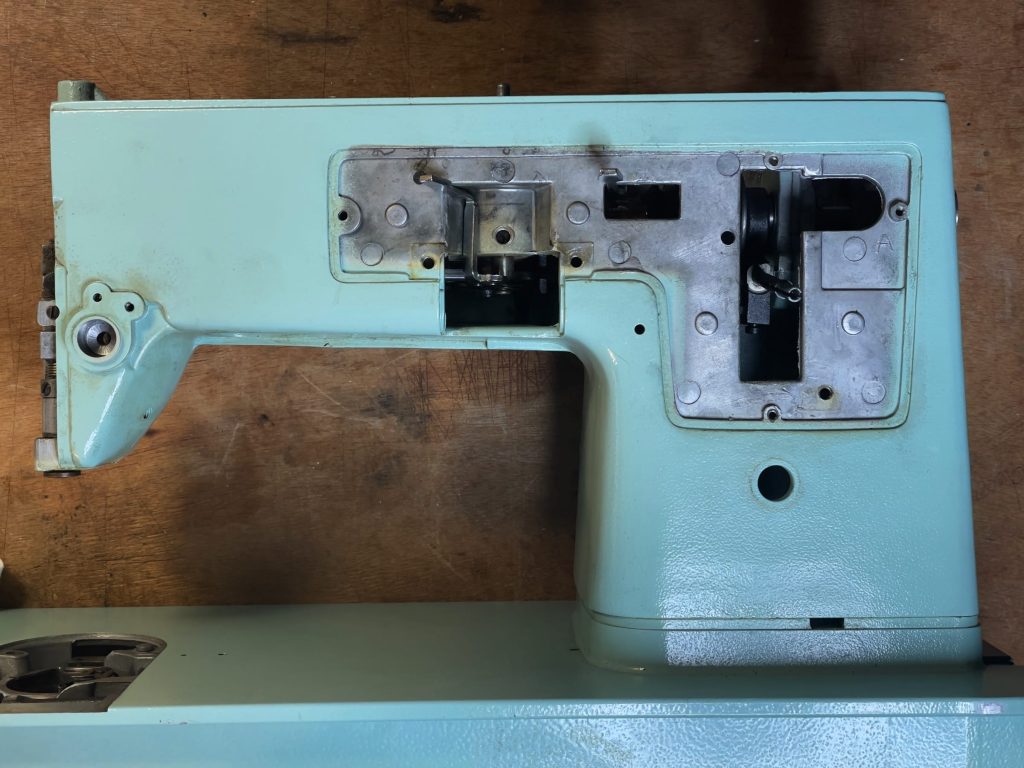

This is my heavily modified, fully refurbished version of the Singer 338 sewing machine. For general information on the original Singer 338 model, you may want to head over to this post.

Made in Great Britain, most likely in the scottish Kilbowie factory, the 338 is a member of an extended family that includes numerous variations on the same body frame — as is customary for Singer.

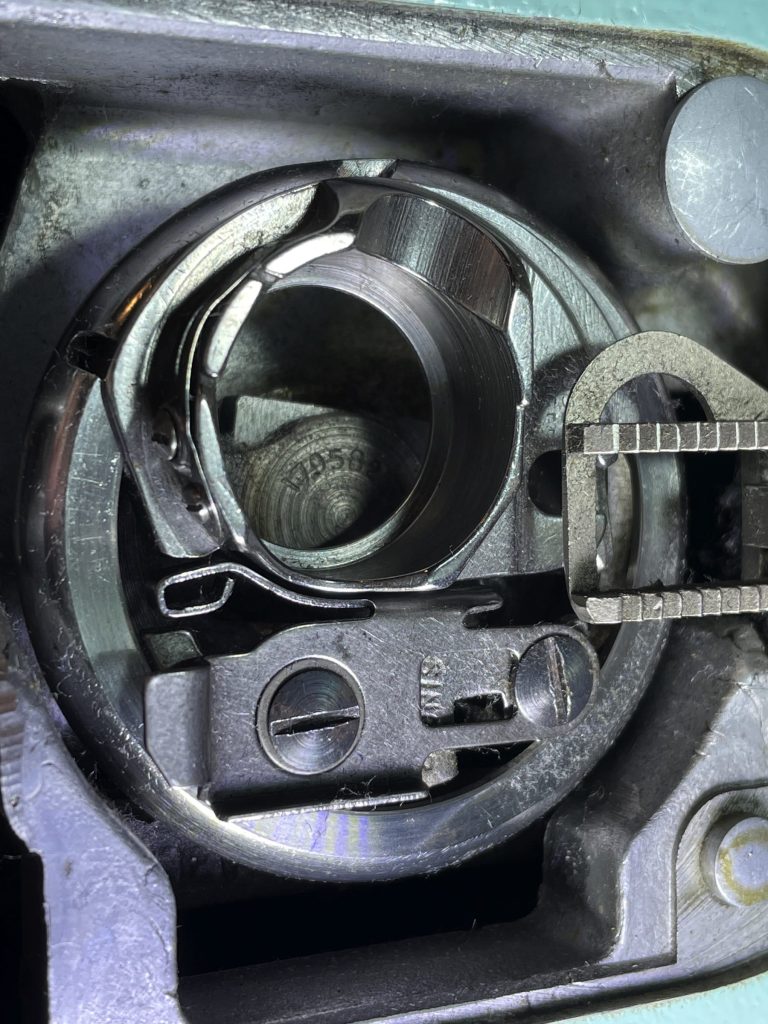

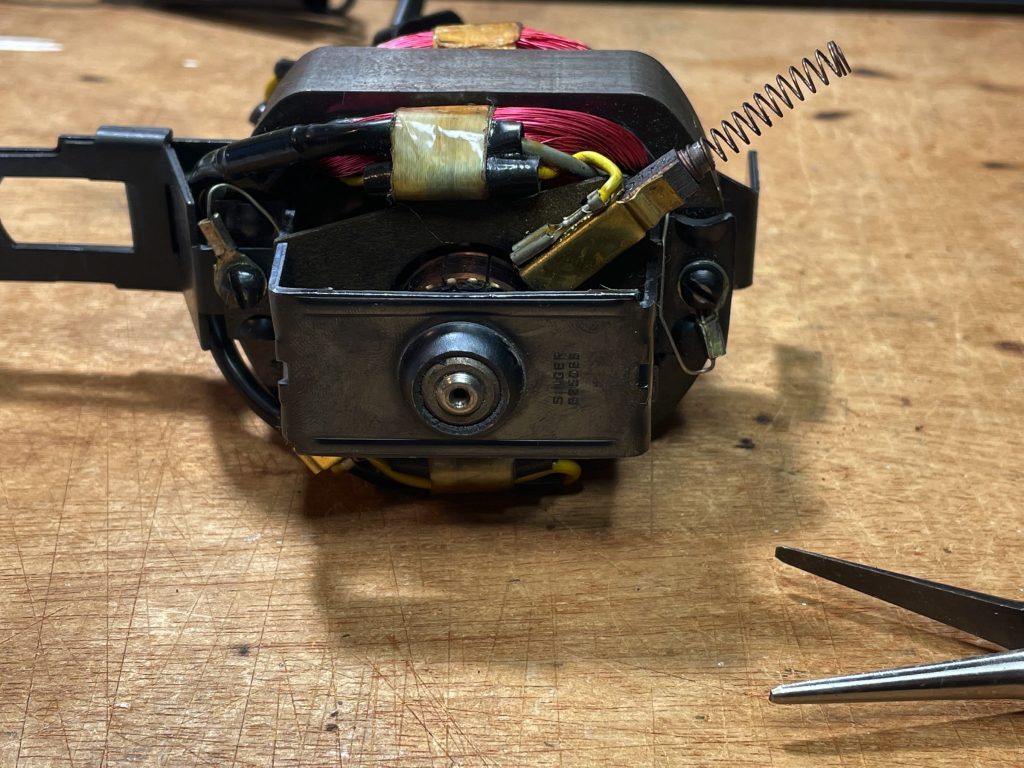

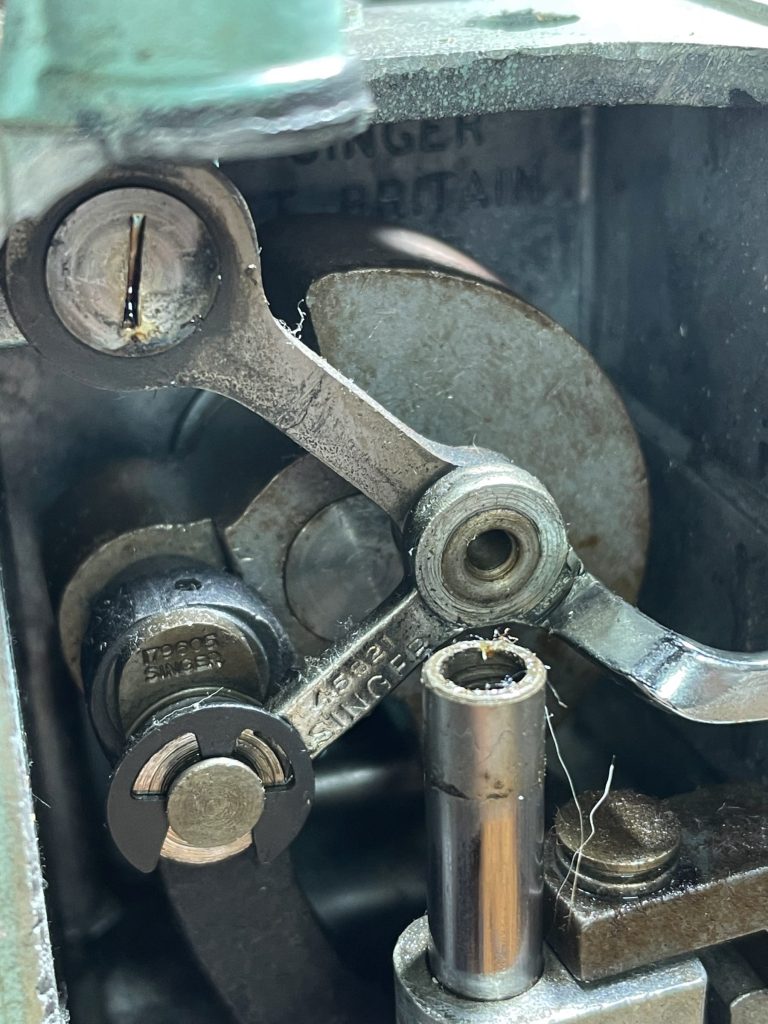

This solid metal beauty is complete with all of its little bits and screws, lovingly restored using parts from at least three 338 machines. Assembled from the ground up on a repainted bare chassis, each individual part, down to the last screw, was cleaned, polished, and fine-tuned for perfect working order. It’s as good as if it had just left the factory, with new transmission belt, revised motor with new brushes, polished hook, and precisely timed.

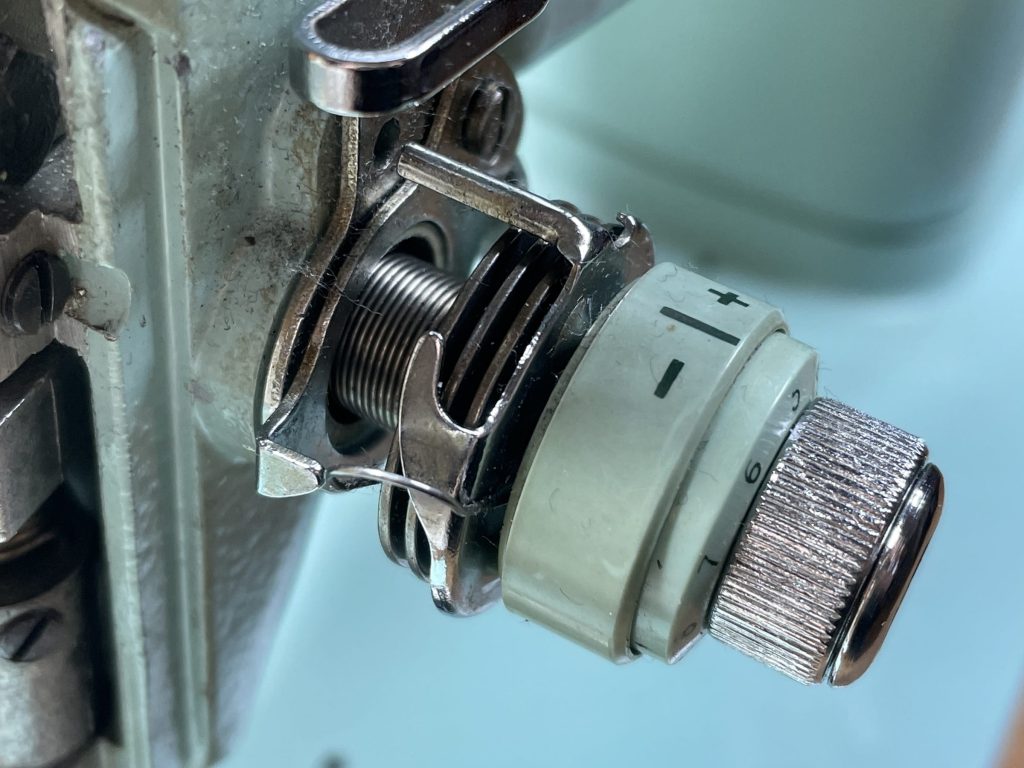

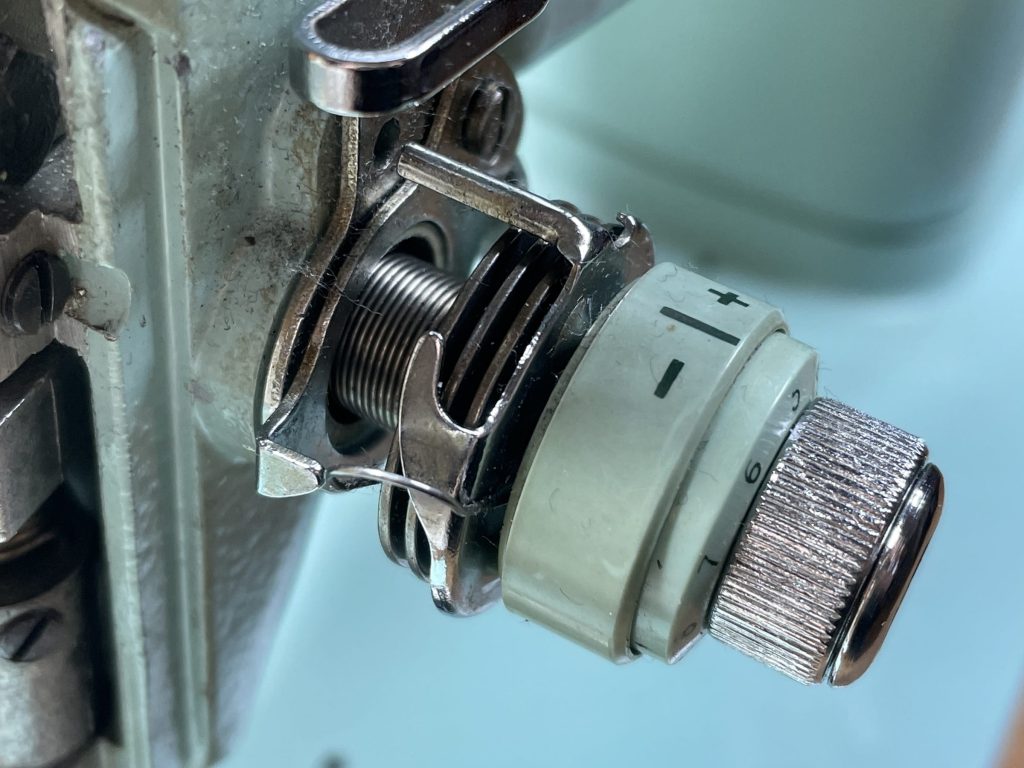

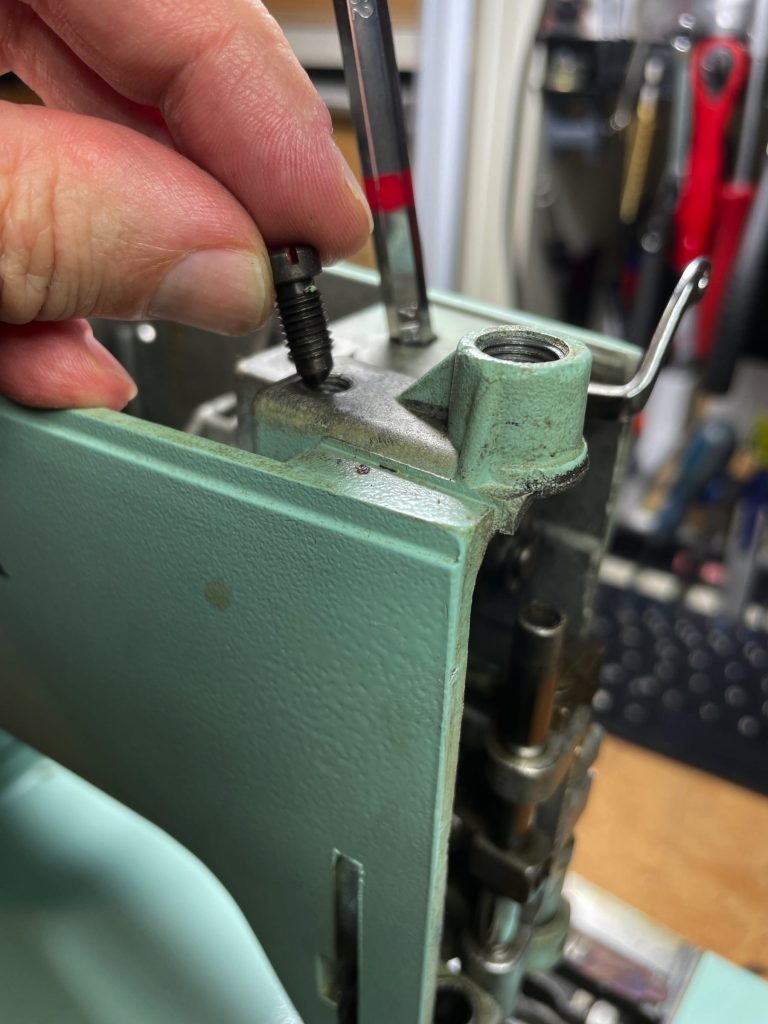

This modification includes one crucial change from the original: the plastic front control panel was replaced with a precision CNC milled aluminium piece, unpainted, with all markings engraved. This will keep its look and legibility for decades to come, with no paint to fade or peel off.

The most important aspect of this upgrade, is that the aluminium provides a much more sturdy support for the needle position control lever. Why is that so relevant? Well, the needle position control is the starting point for setting and adjusting all the operational aspects of the machine. It’s step one in the service manual. Incredibly, it is also what prevents the needle from swinging outside the bounds of the stich plate needle hole, when doing zigzag. Nothing will work correctly unless the three stops of the needle position mechanism are properly situated by the corresponding notches in the plastic front control panel. To make matters worse, the panel is slightly curved under tension when screwed on to the body of the machine: this is why it’s so common to see these control panels broken around the screws that hold them down (over-tightening them also doesn’t help there). And why it’s nearly impossible to find a control panel that’s not broken or cracked. You might also notice that models from this family are invariably missing at least one screw on the panel. Replacing the plastic front panel with a metal one solves this issue, massively improving the accuracy and longevity of the machine.

Other changes include: new metal spool pins instead of the original plastic ones; a larger, more robust metal switch for the light, in keeping with the revised aesthetic of the machine; a black shell for the thread tension unit (its discs, check spring, center rod, position plates, adjustment nut, etc, are all original); and of course, an LED bulb for improved visibility and cool operation.

The spool pins feature a bespoke, custom made crochet base.

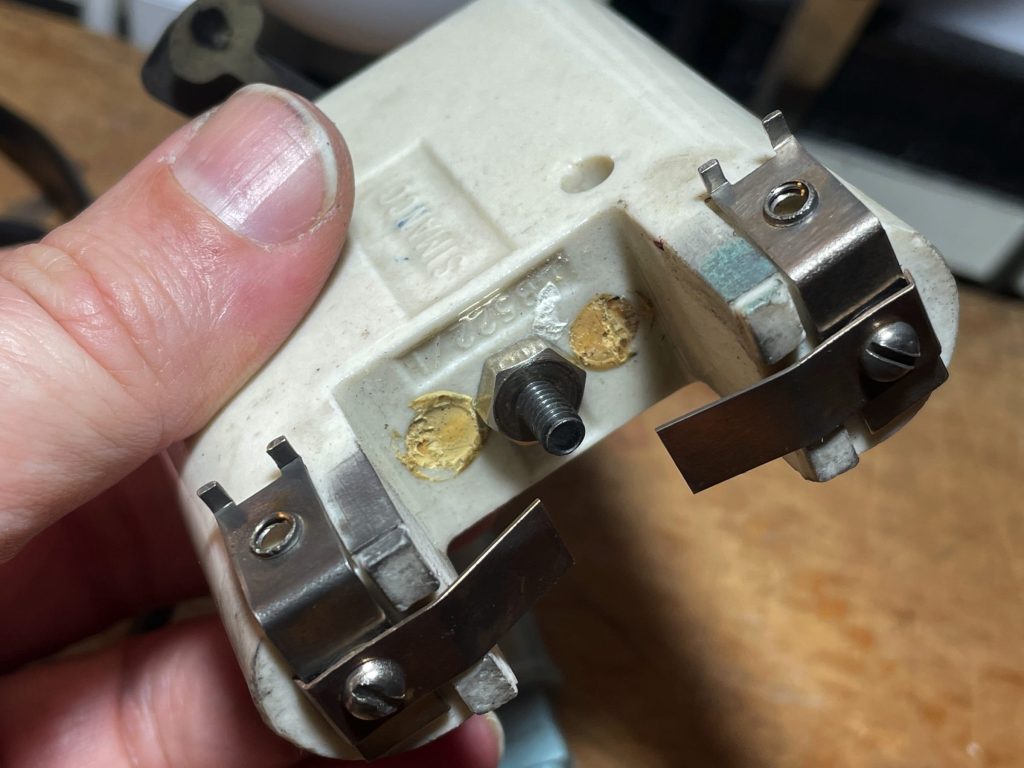

While the original clamshell foot control is present and restored to perfect working order, a new electronic foot control with new cord and plug are also included, for better control and electrical safety. Electronic controllers don’t warm up under prolonged use, improving comfort and reducing fire hazard.

Accessories present:

• Original Singer cardboard accessory box;

• General purpose and straight stitch feet;

• Assortment of fashion discs with utility and decorative stitch patterns;

• Class 66 metal bobbins;

• Spare bobbin case;

• Straight stitch needle plate;

• Raised needle plate cover for darning;

• Spool pin felt pads.

Here are a few “before” pictures for reference…

ID

| Maker | Simanco |

| Brand | Singer |

| Model | 338 |

| Year | |

| Serial number | |

| Origin | USA |

| Manufacture | Scotland |

| Provenance | Portugal |

| Status | Private collection |

SPECS

| Voltage | AC 220 V |

| Bed type | Flat bed |

| Bed extension | No |

| Feet/shank type | Low shank |

| Foot pressure adjustment | Stepless |

| Bobbin type | Class 66, drop-in |

| Hook/race position | Horizontal |

| Hook movement | Reciprocating |

| Bobbin winder | Yes, at hand wheel |

| Spool pins | 2 |

| Bulb type | ba15 |

| Original foot control | Carbon pile, clamshell |

| Current foot control | Electronic |

FEATURES

| Zigzag | 4 mm, with cam |

| Reverse type | Permanent |

| Needle position control | 3 positions |

| Stitch length limiter | Yes, screw-down |

| Stitch width limiter | No |

| Utility stitches | Yes, with cams |

| Decorative stitches | Yes, with cams |

| Stretch stitches | No |

| Auto-reverse stitches | No |

| Double needle provisions | Spool pins and tension discs |

| Drop feed | No |

ACCESSORIES

| Presser feet | General purpose / Straight stitch |

| Straight stitch needle plate | Yes |

| Feed dogs cover plate | Yes |

DOCUMENTS

| User manual | Download PDF: |

| Service manual | Download PDF: |